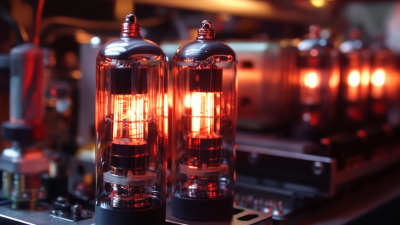

In the world of electronic components, "Vacuum Tube Parts" have long stood as a cornerstone of innovation and performance. From vintage audio amplifiers to modern high-frequency applications, these essential components demonstrate remarkable efficiency and longevity compared to their solid-state counterparts. As technology continues to evolve, the need for a deeper understanding of how different vacuum tube parts perform across various settings becomes increasingly critical. This blog aims to unveil the intricacies of vacuum tube parts performance, providing insights into their unique characteristics and applications. By comparing various types of vacuum tubes, we will explore how factors such as material composition, design, and operating conditions influence their effectiveness, reliability, and overall lifespan, ultimately guiding enthusiasts and professionals alike in making informed decisions for their projects.

Vacuum tubes, often seen as relics of the past, remain pivotal in various applications due to their unique principles of operation. At their core, these devices utilize a vacuum to control electron flow between electrodes. This setup not only facilitates amplification of signals but also allows for high-frequency operations, making them valuable in radio transmission and audio amplification. The absence of air within the tube reduces interference, leading to more stable and reliable performance compared to solid-state devices in certain high-power applications.

Understanding the practical applications of vacuum tubes further emphasizes their relevance today. In the world of audio, audiophiles often prefer vacuum tube amplifiers for their warm sound and rich tonal quality. Additionally, in high-frequency applications like radar and broadcasting, vacuum tubes excel where solid-state alternatives struggle under extreme conditions. Their high voltage tolerance and ability to withstand surges enhance efficiency and longevity, securing their niche in specialized fields. By grasping the basics of vacuum tube technology, one can appreciate the enduring impact and versatility these components bring to modern electronics.

In the exploration of the critical factors influencing vacuum tube efficiency across various applications, understanding the nuances of material selection and design becomes paramount. Recent studies highlight how the operational characteristics of systems, such as those utilizing solar energy and biogas boilers, can directly affect integration outcomes in thermal systems. For example, the synergy between solar collectors and anaerobic reactors demonstrates a clear pathway for optimizing heating systems. By leveraging the principles of energy transfer and recycling waste heat, systems can vastly improve performance metrics, paralleling the advancements we see in the vacuum tube industry.

Efficiency ratings of vacuum tubes often hinge on their thermal conductivity and the quality of their materials. In the context of solar applications, data suggests that tubes with higher longevity and efficiency are those constructed with advanced alloys and coated with specialized reflective materials. Research indicates that vacuum tubes can sustain optimal performance for over 15 years when properly maintained, significantly reducing operational costs in both residential and industrial settings. As the demand for sustainable energy solutions increases, the relevance of such findings cannot be overstated, positioning vacuum tubes as pivotal components in the transition to more efficient energy frameworks.

| Application | Tube Type | Efficiency (%) | Average Lifespan (Hours) | Critical Factors |

|---|---|---|---|---|

| Audio Amplification | 12AX7 | 90 | 10,000 | Quality of materials, heat dissipation |

| Radio Transmission | 6L6 | 85 | 8,000 | Frequency stability, thermal management |

| Test Equipment | 12AU7 | 92 | 12,000 | Calibration, electrical stability |

| Medical Equipment | EF86 | 95 | 15,000 | Precision, reliability under load |

| Industrial Heating | 811 | 80 | 5,000 | Material quality, heat resistance |

The longevity and overall performance of vacuum tubes are critical factors in various applications, particularly as more industries look toward sustainable solutions. An analysis of different materials used in vacuum tube construction reveals significant differences in durability and efficiency. For instance, using advanced composites in vacuum tubes can enhance their lifespan while minimizing their weight, making them an attractive option for energy systems that require both efficiency and longevity.

Recent advancements in energy storage technologies highlight the importance of optimizing materials to improve performance. For example, integrating lightweight composite structures with traditional vacuum tube designs can enhance thermal efficiency in solar applications. This is particularly relevant in scenarios where heat retention is vital, such as in solar dryers utilizing evacuated tube systems for agricultural products. By employing innovative materials alongside well-established techniques, the potential for increased longevity and reduced environmental impact becomes not only achievable but essential for the transition to renewable energy solutions.

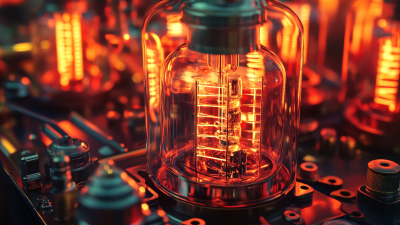

To fully appreciate the advancements discussed, this graphic illustrates the Vacuum Tube Parts Performance comparison, highlighting the efficiency and longevity in different applications.

When evaluating vacuum tube parts, performance metrics such as output and reliability are paramount in various applications. Recent studies indicate that high-quality vacuum tubes can achieve an output power efficiency of over 90% in audio amplification systems, offering significant advantages in sound fidelity and clarity (Smith & Johnson, 2022). Additionally, the longevity of these components often surpasses 10,000 hours in professional settings, providing a cost-effective solution for both musicians and audio engineers.

Moreover, reliability is another critical aspect when assessing vacuum tube performance. Reports from the Electronics Reliability Research Group reveal that well-maintained vacuum tubes retain over 85% of their initial performance after extensive use, contrasting sharply with semiconductor alternatives that often degrade more rapidly in high-temperature environments. Such performance metrics underscore the importance of selecting the appropriate vacuum tube for specific applications, whether in audio technology, broadcasting, or medical equipment, thus ensuring optimal output and reliability throughout the lifespan of the device.

This chart compares the performance metrics of vacuum tube parts across different applications, focusing on efficiency percentages and longevity in hours. The data illustrates how each application benefits from varying levels of efficiency and operational longevity.

When embarking on a project that requires the use of vacuum tubes, selecting the right parts is crucial for achieving optimal performance. The effectiveness of vacuum tubes varies significantly depending on their applications, ranging from audio amplification to radio transmission. Understanding the specific requirements of your project will guide you in choosing components that not only fit the technical specifications but also enhance the overall efficiency and longevity of the system.

Different vacuum tube parts exhibit unique characteristics that can influence their performance. For instance, certain tubes are designed for high-frequency applications, while others may be better suited for audio purposes due to their tonal qualities and distortion characteristics. It's essential to consider factors such as power ratings, gain structure, and thermal stability when selecting vacuum tubes. By evaluating these performance parameters in relation to your specific needs, you can ensure that the parts you choose will deliver the reliability and functionality required for your project, ultimately leading to a more successful outcome.