As we forge ahead into 2025, the cable assembling industry is poised for transformative growth driven by technological advancements and increasing demand. According to a recent market report by Mordor Intelligence, the global cable assembly market is projected to reach USD 200 billion by 2025, reflecting a compound annual growth rate (CAGR) of over 5%. This growth is primarily fueled by the rising need for high-quality, customized solutions in sectors such as telecommunications, automotive, and consumer electronics.

Leading manufacturers in China are at the forefront of this evolution, leveraging innovative techniques and state-of-the-art machinery to deliver unmatched quality in cable assembling. As the industry evolves, understanding the emerging trends will be essential for stakeholders looking to optimize their operations and capitalize on new opportunities.

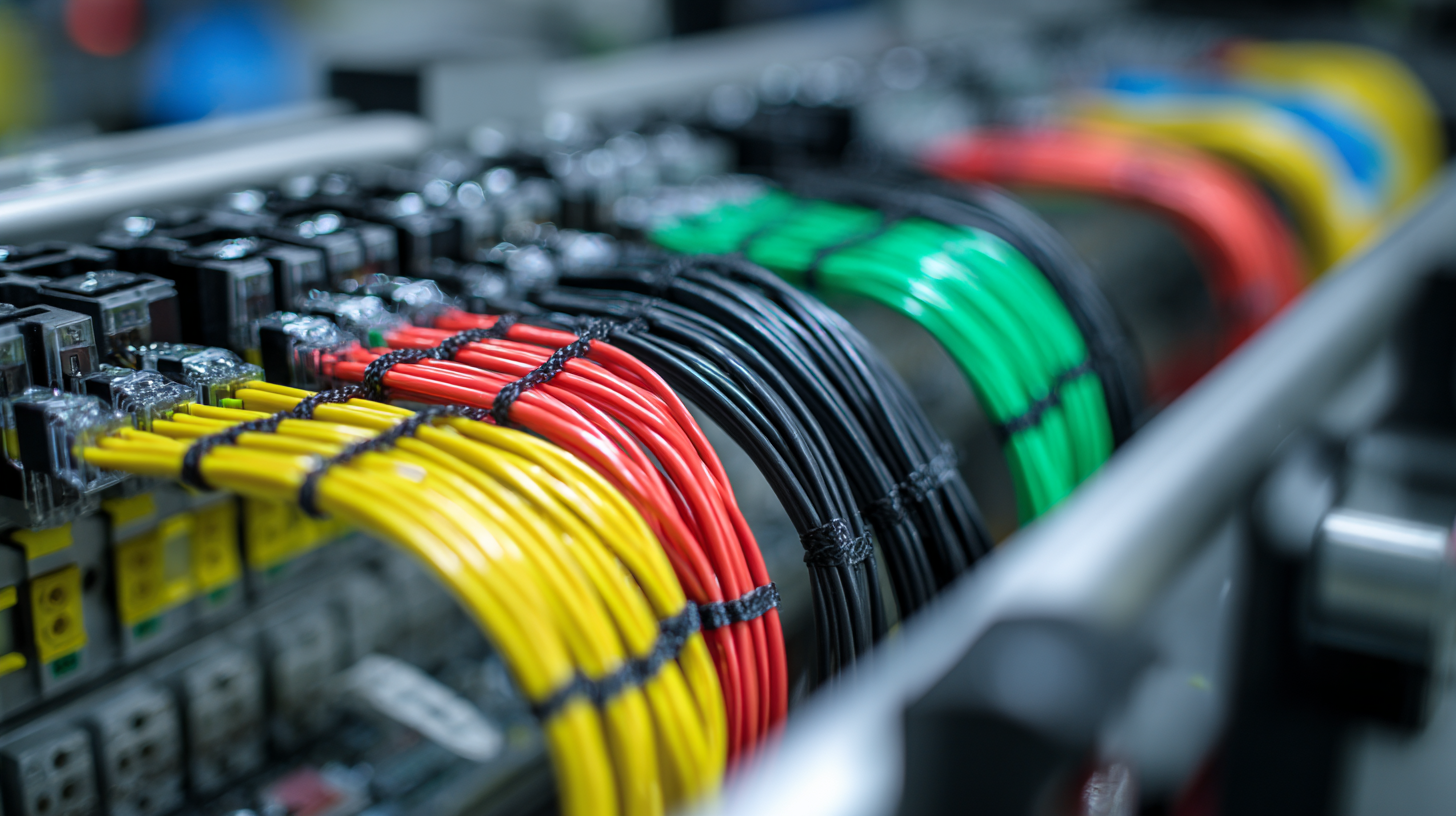

In today's competitive global market, China's manufacturing landscape has emerged as a beacon of excellence, particularly in the field of cable assembling. The nation's commitment to quality, innovation, and advanced technology has positioned it as a leading hub for cable production. Manufacturers are continuously refining their processes, ensuring that every product meets the highest standards. This focus on excellence is evident in the meticulous craftsmanship and rigorous testing protocols employed throughout the assembly process.

In today's competitive global market, China's manufacturing landscape has emerged as a beacon of excellence, particularly in the field of cable assembling. The nation's commitment to quality, innovation, and advanced technology has positioned it as a leading hub for cable production. Manufacturers are continuously refining their processes, ensuring that every product meets the highest standards. This focus on excellence is evident in the meticulous craftsmanship and rigorous testing protocols employed throughout the assembly process.

The unique blend of cutting-edge technology and traditional manufacturing techniques allows Chinese companies to produce a wide variety of cables that cater to diverse industries. From telecommunications to automotive, the versatility and reliability of these cables are unmatched. With a strong emphasis on research and development, these manufacturers are not only enhancing product performance but also driving sustainability initiatives within the industry. As the demand for high-quality cable solutions continues to rise, China stands prepared to meet and exceed expectations with unwavering commitment to excellence in cable assembling.

China's cable assembly industry has witnessed remarkable growth and transformation, driven by groundbreaking technological innovations. Manufacturers are increasingly adopting automation and robotics in their production processes, enhancing efficiency and reducing human error. These advanced technologies not only streamline operations but also ensure consistent product quality, which is crucial in meeting the rising global demand for reliable and high-performance cable assemblies.

Moreover, the integration of smart manufacturing practices, such as the Internet of Things (IoT) and data analytics, allows companies to optimize their production lines and monitor processes in real-time. This data-driven approach enables manufacturers to swiftly identify and address potential issues, further elevating the quality of their products. As these technologies continue to evolve, they play a pivotal role in positioning China's cable assembly sector as a leader in the global market, known for its unmatched quality and innovation.

In the highly competitive world of cable assembling, quality control practices are crucial for manufacturers to stand out. China's leading manufacturers have implemented stringent quality assurance measures that not only adhere to international standards but also often exceed them. According to a report by Markets and Markets, the global cable assembly market is projected to reach USD 183.49 billion by 2026, highlighting the significance of quality in maintaining market share. This growing demand emphasizes the importance of rigorous testing procedures, which ensure that products meet safety regulations and functionality criteria.

Furthermore, China's manufacturers leverage advanced technologies such as Automated Optical Inspection (AOI) and X-ray inspection systems to catch defects early in the production process. These innovations have significantly reduced the rate of returns due to quality issues, enhancing customer satisfaction and trust. Tips for selecting a reliable cable manufacturer include checking for certifications such as ISO 9001 and reviewing their quality control processes. Always inquire about their testing protocols and the frequency of third-party audits to ensure you are partnering with a manufacturer that prioritizes excellence.

Additionally, it's essential to understand the lifecycle of the cables being assembled. Request data on the materials used, as well as the environmental impact of their production. Awareness of these factors can guide you in making informed decisions, ultimately supporting the selection of a manufacturer that not only focuses on quality but also sustainability.

| Product Type | Material | Application | Quality Control Method | Certifications |

|---|---|---|---|---|

| Power Cables | Copper | Industrial Equipment | ISO 9001 | CE, RoHS |

| Data Cables | Aluminum | Telecommunications | IEC 60603 | UL, CSA |

| Coaxial Cables | Copper | Broadcasting | TUV | ISO, FCC |

| Fiber Optic Cables | Glass | Internet | ISO 14001 | BICSI |

As industries across the globe trend towards sustainability, China's cable assembling sector is emerging as a leader in eco-friendly practices. With an annual growth rate of 6.5% in the global cable market, as reported by Market Research Future, China is not only a key player but also sets the benchmark for sustainable production methods. The country’s leading manufacturers are investing heavily in green technologies, such as biodegradable insulation materials and energy-efficient machinery, which significantly reduce carbon footprints during production.

Moreover, a recent study by the International Cable and Network Association highlights that the shift towards sustainable cable assembling can lead to a decrease in hazardous waste by up to 30%. Chinese manufacturers are increasingly adopting circular economy principles by recycling old cables and reusing materials in their production processes. This commitment is reflected in their certifications, with over 70% of prominent manufacturers obtaining ISO 14001 for environmental management. Ultimately, China's proactive approach serves as an inspiring model for other nations aiming to achieve sustainable industrial growth while maintaining high-quality standards.

In recent years, China's cable assembling industry has positioned itself as a leader on the global stage, dominating with unmatched quality and efficiency. According to a report by Market Research Future, the global cable assembly market is projected to reach USD 209.4 billion by 2025, with Asia-Pacific, particularly China, accounting for a substantial share. The country boasts cutting-edge technology and streamlined processes, enabling manufacturers to deliver products that meet rigorous international standards.

When comparing global cable assembling standards, it becomes clear that China's innovative approaches set it apart. For instance, China leverages automation and robotics, which has resulted in a 30% reduction in production costs over the past five years. This focus on efficiency not only enhances the quality of the end product but also allows for quicker turnaround times, making Chinese manufacturers formidable competitors in the global marketplace.

Tip: When sourcing cable assemblies, consider manufacturers that comply with international standards like ISO 9001 and RoHS, as these certifications ensure quality and environmental compliance. Additionally, look for companies with strong customer reviews to gauge their reliability and service levels.

In conclusion, the combination of advanced manufacturing techniques and a commitment to quality positions Chinese manufacturers at the forefront of the cable assembling industry, making them an ideal choice for businesses worldwide.