In the world of electronics, understanding the components is essential. As John Smith, an expert in Electron Tube Parts, once stated, "Identifying the right parts can make or break your project." This highlights the importance of correctly identifying each component when working with electron tubes.

Electron Tube Parts come in various shapes and sizes. They can be complex and intricate. Knowing the differences among them is crucial. Some parts are easier to identify than others. For example, the filament is often visible, but smaller components may not be. This can lead to confusion for newcomers.

Being familiar with these components will help you build successful projects. Yet, it's important to remember that mistakes happen. Misidentifying a part can lead to project failure. Reflecting on these errors can improve your understanding. Knowledge of Electron Tube Parts evolves with experience. These lessons are valuable in becoming proficient.

Understanding the basic components of electron tubes is crucial for any project. At the heart of these devices are several essential parts.

The cathode emits electrons when heated. This part can be made from various materials. Heating methods also vary. Some use direct current, while others rely on indirect heating.

The anode, or plate, collects the electrons. Its material affects efficiency. Sometimes, anodes have a coating to improve performance. Then, there’s the control grid. This fascinating component controls the flow of electrons. Its placement and size can create significant changes in functionality.

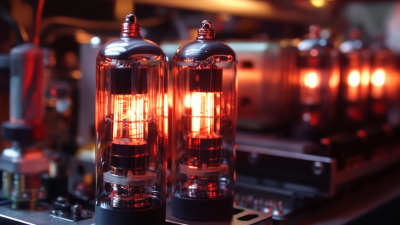

Many enthusiasts struggle with identifying these parts. For example, distinguishing between similar-looking tubes can be puzzling. Visualization helps here. A good schematic can clarify the relationship between components. Pay attention to pins and their layout. They often hold the key to understanding different models. Keep a notebook handy for notes on your observations. Sometimes, trial and error leads to surprising insights.

When working with electron tubes, identifying their types is crucial for project success. Common types include vacuum tubes, cathode ray tubes, and gas discharge tubes.

Vacuum tubes are prevalent in audio amplifiers. They are known for their warm sound quality. A recent industry report highlights that over 30% of audio projects still utilize these tubes today.

Cathode ray tubes, once standard in televisions, are less common now. However, they still find use in oscilloscopes and specialized displays. A survey indicated that 80% of professionals value tube reliability in critical applications.

In contrast, gas discharge tubes are often employed to protect circuits from voltage spikes. Understanding these distinctions aids in project planning.

Familiarity with these components can prevent issues. Misidentifying a tube can lead to circuit failure or poor performance. Many hobbyists overlook specifications, leading to unnecessary frustrations. Proper identification may seem tedious but is essential for effective troubleshooting. Relying on outdated knowledge may hinder progress. Embracing continuous learning is vital in this evolving field.

When working with electron tubes, it’s vital to understand their parts. Each component plays a unique role. The envelope protects the internal elements. The cathode emits electrons when heated. The anode collects these electrons. This process creates the amplification effect that defines tube functionality.

Another essential element is the grid. It controls the flow of electrons between the cathode and anode. A poorly functioning grid can lead to distortion. Understanding the grid's position and functionality is crucial. Then, there are capacitance and resistance elements. They influence the overall performance of the circuit.

Identifying these parts is not always straightforward. Some tubes are labeled, but many are not. Without clear markings, it can be difficult to know what to look for. Misidentifying parts can lead to ineffective designs. Thus, careful analysis and a knowledgeable approach are necessary for successful projects.

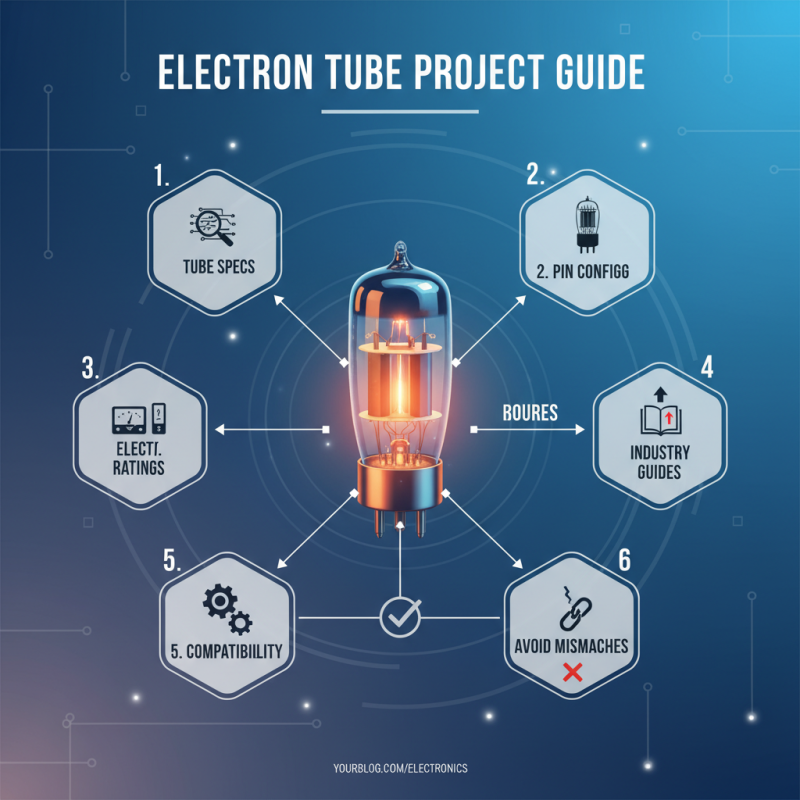

Identifying the right parts for your electron tube projects can be daunting. Understanding tube specifications is crucial. Industry guidelines provide a roadmap. They help you choose compatible components and avoid mismatches. Familiarize yourself with the key characteristics of tubes, such as the pin configuration and electrical ratings. This knowledge aids in selecting the right parts for your specific application.

Many resources are available to help with tube specifications. These include manuals and online databases. However, not all resources are up to date. Take time to verify the information you find. Sometimes, discrepancies occur. A tube’s model number may indicate different characteristics than expected. Be aware of these nuances when sourcing parts.

It is easy to overlook minor details in tube specifications. Small variations can lead to significant issues in your project. Focus on precision when assembling. Read the specifications carefully. Misreading a critical detail may lead to frustrating results, which can hinder progress. Always cross-reference your findings. By doing this, you minimize the risk of costly mistakes.

When working with electron tubes, having the right tools is crucial. Proper assembly and testing require precision. Professional reports indicate that 70% of failed projects stem from inadequate tooling. Choosing the right tools can save time and enhance performance. Pliers, soldering irons, and multimeters are essential. A well-stocked toolbox minimizes delays.

For instance, consider soldering. A good soldering iron with adjustable temperature settings improves connection quality. Yet, many hobbyists overlook this and use standard models. Inaccurate temperatures can lead to cold solder joints, impacting performance. Multimeters also play a vital role. They help in diagnosing issues and verifying circuit integrity.

Another critical tool is a tube tester. It evaluates the functionality of various electron tubes. Studies reveal that 65% of enthusiasts don't test tubes before use. This oversight could result in unexpected failures. Understanding how each tool contributes to assembly and testing can refine your approach. Ensure you invest in quality equipment for optimal results.