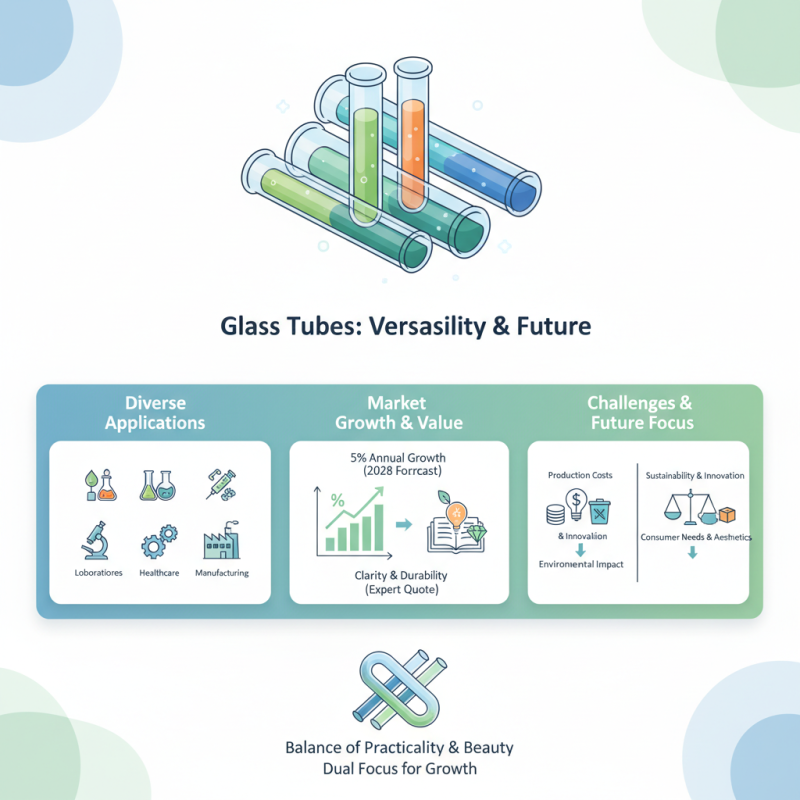

Glass tubes are versatile tools in various industries. They are used in laboratories, healthcare, and manufacturing. According to a recent market report by Global Market Insights, the glass tube market is expected to grow by 5% annually through 2028. This growth highlights the ongoing demand for efficient and reliable packaging solutions.

Dr. Emily Chen, a notable expert in glass manufacturing, states, "Glass tubes provide unmatched clarity and durability for a variety of applications." This reflects the importance of glass tubes in critical environments. However, the industry faces challenges. Production costs and the environmental impact of glass waste are pressing issues that require innovative solutions.

Glass tubes are not just functional; they also carry aesthetic value in design. They embody a balance between practicality and beauty. As the industry evolves, stakeholders must address sustainability while meeting consumer needs. This dual focus is essential for future growth and relevance.

A glass tube is a hollow cylinder made from glass. It can vary greatly in size, thickness, and purpose. The transparency of glass allows for visual inspection of contents. This characteristic is essential in scientific and medical settings where observation is crucial. Some tubes are clear, while others may have colored or frosted surfaces.

Glass tubes are commonly used in laboratories for experiments. They serve as containers for liquids and gases. Many people recognize them as test tubes or beakers. The glass material is non-reactive, making it ideal for chemical reactions. However, handling glass requires care. A careless moment can lead to breakage and injury.

In addition to science, glass tubes are used in construction and art. They can be found in architectural designs, adding elegance to buildings. In art, they serve as mediums for various creative projects. Their versatility makes them popular, yet their fragility reminds us to proceed with caution.

The history of glass tube manufacturing is fascinating. It dates back to ancient times. Artisans crafted glass using basic techniques. These methods evolved gradually. Early glass tubes served basic purposes, mainly for storage or decoration.

During the Renaissance, techniques advanced significantly. Innovators began creating glass tubes for scientific use. Alchemists utilized them in experiments. This was a pivotal development, enhancing both chemistry and medicine. The introduction of clearer glass allowed for better visibility. It was a game changer for laboratory practices.

Tips: When exploring glass tube applications, consider how the design impacts function. A well-shaped tube can improve fluid dynamics. Don't overlook the importance of thickness in glass. It can affect durability and usage. Understanding these factors can guide improved designs in modern applications.

Glass tubes are versatile and widely used in various industries due to their unique properties. They are transparent, allowing visibility of contents, and are also resistant to chemicals. In laboratories, glass tubes serve as test tubes, storage containers, and reaction vessels. Their reliability is crucial for accurate experiments and analyses.

In construction, glass tubes find applications in decorative lighting and architectural design. They can be used as protective covers for light fixtures or as design elements in modern architecture. The flexibility in shaping and applying glass adds an aesthetic touch.

Furthermore, in the healthcare sector, glass tubes are used for packaging pharmaceuticals. These tubes maintain the integrity of medications by providing a barrier against moisture and contamination. However, they can be fragile. This fragility demands careful handling, leading to potential waste and challenges in recycling. Despite these imperfections, their benefits often outweigh the drawbacks, proving their ongoing relevance in multiple fields.

| Application | Industry | Specifications | Benefits |

|---|---|---|---|

| Laboratory Equipment | Scientific | Borosilicate Glass, Various Diameters | High thermal resistance, Chemically inert |

| Medical Tubing | Healthcare | Soft Glass, Sterile | Biocompatible, Easy to sterilize |

| Display Technology | Electronics | Thin Glass, Custom Shapes | Lightweight, High clarity |

| Lighting Applications | Construction | Clear or Colored Glass Tubes | Durable, Aesthetic appeal |

| Chemical Handling | Pharmaceutical | Corrosion-Resistant Glass | Safe for reactive substances, Longevity |

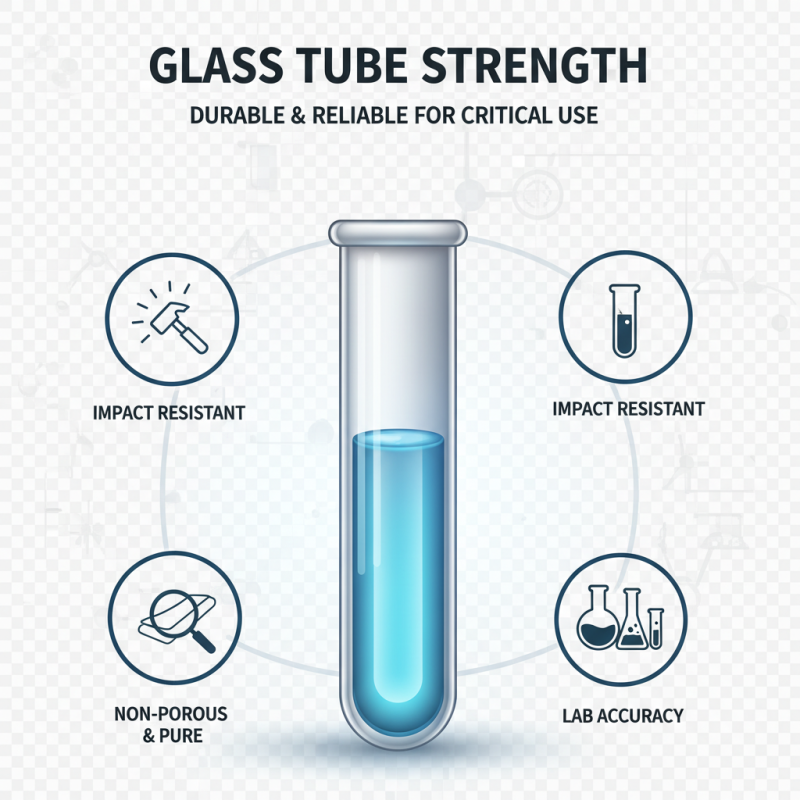

Glass tubes exhibit remarkable durability. Their structure is resistant to physical impacts. This makes them ideal for various applications. They can endure daily wear and tear. The material is also non-porous, preventing contamination. In laboratory settings, this is essential. Researchers rely on glass tubes for accurate results.

Thermal resistance is another key property. Glass tubes can withstand significant temperature changes. This is particularly important in experiments involving heat. They can handle sudden shifts without breaking. However, caution is needed when using extreme temperatures. Not every glass tube is created equal. Some may have limitations that aren't always apparent.

Choosing the right glass tube requires careful thought. Pay attention to thickness and quality. These factors can impact performance significantly. While glass is durable, it can also be fragile under certain conditions. Understanding how to handle them properly is crucial. Misjudging this could lead to accidents. Ultimately, glass tubes remain a versatile choice for many fields.

The glass tube market is witnessing notable growth. Research indicates that the global glass tube market size was valued at around $3 billion in 2022. Projections suggest it will grow at a CAGR of approximately 5% by 2030. This growth is driven by advances in technology and increased demand in various sectors.

The medical industry heavily relies on glass tubes. They are commonly used for storing samples and laboratory testing. Additionally, the rise in healthcare and biotechnology sectors has intensified demand. In the packaging industry, glass tubes are favored for their ability to preserve product integrity. However, sustainability concerns often arise with their disposal. Recycling options are growing, but they still require refinement.

Future trends indicate a shift toward innovative designs and eco-friendly materials. Manufacturers are exploring alternative materials to reduce environmental impact. Some experts highlight challenges in production efficiency. A balance between automation and artisanal craftsmanship is necessary. For now, glass tubes remain essential across diverse applications, but their evolution must consider sustainability.