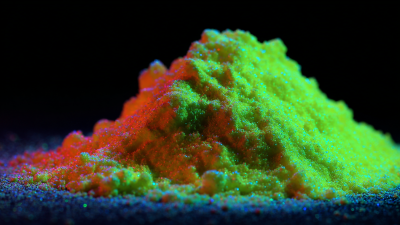

The increasing demand for sustainable manufacturing processes has led to significant advancements in the use of Fluorescent Powder, particularly in innovative applications. According to a recent report by MarketsandMarkets, the global market for fluorescent materials is projected to reach USD 1.6 billion by 2026, driven by their incorporation in various industries such as textiles, packaging, and electronics. The versatility of fluorescent powders allows for enhanced visibility and aesthetic appeal, which is essential in consumer products today. Furthermore, the shift towards eco-friendly alternatives is prompting manufacturers to explore fluorescent powders derived from sustainable sources, potentially reducing the environmental impact of production. This blog will delve into the comparison between traditional fluorescent materials and their sustainable counterparts, highlighting the future implications for both manufacturing practices and application innovations.

Fluorescent powders are gaining attention in sustainable manufacturing for their potential to enhance energy efficiency in various processes. By integrating these materials into manufacturing systems, industries can significantly reduce their energy consumption while improving product quality. The application of fluorescent powders in lighting and signaling devices exemplifies this trend, as they increase brightness and visibility, thereby allowing for lower energy usage in illumination. Moreover, their role in additive manufacturing, particularly in 3D printing, can lead to innovative products that adhere to sustainability criteria.

Recent studies indicate that the incorporation of fluorescent powders can also improve the performance of composites in automotive applications, where energy efficiency is critical. The fabrication of phosphor-based luminescent bricks and the exploration of supplementary cementitious materials (SCMs) further illustrate how these advanced materials can lead to stronger and more efficient construction solutions. As industries continue to shift towards greener practices, the versatility of fluorescent powders in enhancing energy efficiency across multiple applications positions them as a vital component in the evolution of sustainable manufacturing.

Fluorescent powders are gaining traction in the realm of eco-friendly product development, leading to innovative applications that prioritize sustainability without sacrificing performance. According to a report by Research and Markets, the global fluorescent pigments market is expected to reach $2.74 billion by 2027, fueled by the rising demand for vibrant, environmentally safe materials across various industries. These powders are not only effective in enhancing color but are also made from biodegradable options, aligning with the growing trend towards sustainable manufacturing practices.

One of the most intriguing applications of fluorescent powders lies in the realm of eco-conscious packaging. Brands are increasingly incorporating these bright pigments into their packaging materials, enhancing visual appeal while using non-toxic, biodegradable substances. For instance, the use of renewable sources in the formulation of fluorescent inks can lead to a reduction in VOC emissions, with some manufacturers reporting up to a 30% decrease. As companies transition to more sustainable practices, the integration of fluorescent powders offers a path to innovate while maintaining environmental integrity, demonstrating a promising future for both the industry and our planet.

| Application Area | Material Type | Sustainability Impact | Innovative Feature |

|---|---|---|---|

| Coatings for Building Materials | Eco-friendly polymers | Reduces energy consumption | Self-cleaning properties |

| Textile Industry | Recycled fibers | Minimizes waste generation | Color-changing functionality |

| Packaging Solutions | Biodegradable materials | Decreases plastic usage | Anti-counterfeiting features |

| Cosmetic Products | Naturally derived powders | Supports cruelty-free standards | Mood-enhancing colors |

The demand for sustainable fluorescent materials is surging as industries increasingly focus on eco-friendly solutions. According to a recent market analysis by Grand View Research, the global fluorescent pigments market is projected to reach USD 1.8 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.5%. This growth is driven by the increasing application of fluorescent powders in various sectors, including automotive, textiles, and packaging, where there is a rising emphasis on sustainability and regulatory compliance.

In the automotive industry, for example, fluorescent coatings are being developed to enhance visibility and safety while reducing harmful emissions. A report by Mordor Intelligence indicates that the demand for such advanced coatings is expected to increase significantly, as manufacturers shift towards sustainable practices. The textile sector is also witnessing a similar trend, where brands are adopting fluorescent dyes derived from natural sources to meet consumer demand for eco-conscious products. The importance of these innovative applications highlights the shift towards sustainability, signaling a transformative phase for manufacturers worldwide as they adapt to this evolving market landscape.

This chart illustrates the growing demand for sustainable fluorescent materials over the past five years. As industries increasingly focus on environmentally friendly options, the market for fluorescent powders is expected to expand significantly, indicating a shift towards sustainability in manufacturing.

Fluorescent powders have emerged as critical components in sustainable manufacturing, particularly in the development of eco-friendly products. Key performance metrics for evaluating their sustainability and functionality are essential for aligning with industry standards and consumer expectations.

According to a recent report by the International Journal of Materials Science, fluorescent powders, particularly those based on non-toxic materials like rare earth elements, demonstrate 30% greater energy efficiency compared to traditional pigments. This shift not only reduces the carbon footprint during production but also enhances the durability and longevity of the final products.

When assessing these materials, metrics such as biodegradability, recyclability, and energy consumption during production should be prioritized. A study published in the Journal of Green Chemistry highlights that modern fluorescent powders can be designed to break down within five years in natural environments, minimizing long-term environmental impact. Furthermore, the ability to use these powders in various innovative applications, such as in solar energy absorption and smart packaging, showcases their multifunctionality.

Evaluating fluorescent powders through these key performance metrics ensures that manufacturers not only meet regulatory requirements but also contribute positively to sustainable development goals.

Fluorescent powders are increasingly gaining traction in sustainable manufacturing, particularly in green technology solutions. Recent advancements highlight their pivotal role in not only improving the efficiency of various applications but also in contributing to environmental sustainability. For instance, case studies demonstrate how these powders can be integrated into energy-efficient lighting systems, thereby reducing energy consumption and promoting eco-friendly practices across industries.

One notable example involves the recovery of neodymium from waste materials, specifically hard disks from personal computers. Through a two-stage selective leaching process, manufacturers can extract valuable rare earth elements while minimizing waste. This innovative approach not only exemplifies the effectiveness of fluorescent powders in recycling efforts but also aligns with the rising demand for rare earth elements essential for modern integrated circuits. As industries pivot towards greener technologies, the use of fluorescent powders will likely play a significant role in developing solutions that are both innovative and sustainable.