As the global demand for efficient and reliable power transmission systems grows, the significance of advancements in cable assembling cannot be overstated. According to a report by MarketsandMarkets, the cable assemblies market is projected to reach USD 119.27 billion by 2024, reflecting a compound annual growth rate (CAGR) of 7.5% from 2019 to 2024. The 138th China Import and Export Fair in 2025 serves as a pivotal platform for showcasing innovative techniques and technologies in cable assembling, enabling manufacturers to enhance product performance and meet the evolving needs of various industries. As participants gather to explore cutting-edge solutions, trends such as automation, miniaturization, and eco-friendly materials are expected to dominate the discussions, driving the future of cable assemblies towards greater efficiency and sustainability.

As the global demand for efficient and reliable power transmission systems grows, the significance of advancements in cable assembling cannot be overstated. According to a report by MarketsandMarkets, the cable assemblies market is projected to reach USD 119.27 billion by 2024, reflecting a compound annual growth rate (CAGR) of 7.5% from 2019 to 2024. The 138th China Import and Export Fair in 2025 serves as a pivotal platform for showcasing innovative techniques and technologies in cable assembling, enabling manufacturers to enhance product performance and meet the evolving needs of various industries. As participants gather to explore cutting-edge solutions, trends such as automation, miniaturization, and eco-friendly materials are expected to dominate the discussions, driving the future of cable assemblies towards greater efficiency and sustainability.

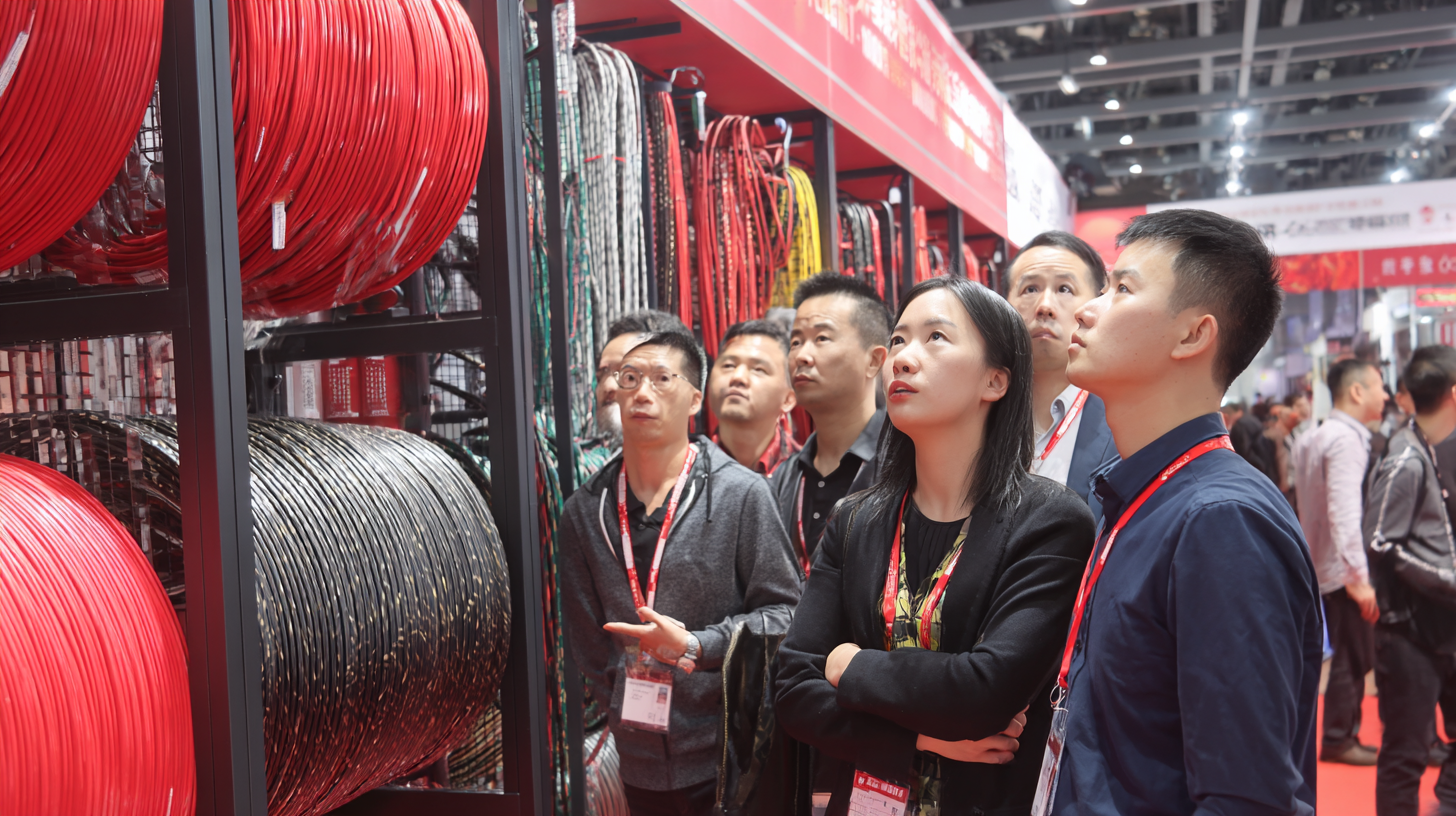

The 138th China Import and Export Fair 2025 is set to be a pioneering event for the cable assembly industry, showcasing a plethora of innovative technologies that aim to enhance performance and efficiency. Among the innovations highlighted at the fair is an advanced multi-cable entry system, which leverages a unique gel insert for improved sealing and protection. Such technology not only streamlines installation processes but also brings enhanced versatility for various applications.

The 138th China Import and Export Fair 2025 is set to be a pioneering event for the cable assembly industry, showcasing a plethora of innovative technologies that aim to enhance performance and efficiency. Among the innovations highlighted at the fair is an advanced multi-cable entry system, which leverages a unique gel insert for improved sealing and protection. Such technology not only streamlines installation processes but also brings enhanced versatility for various applications.

Tips: When exploring new cable assembly technologies, consider the importance of adaptability. Innovations like multi-cable bushings can significantly reduce the complexity of installations, allowing for quicker and more efficient setups. Keep an eye on developments in different sectors, as cross-industry innovations often lead to unexpected breakthroughs in design and functionality.

Additionally, the fair will also present solutions aimed at emerging trends within the electric vehicle market. This includes cutting-edge connectors designed specifically for electric vehicle charging, which reflect the growing emphasis on sustainability within the tech landscape. Attendees are encouraged to engage with exhibitors to gain insights into how these developments can be integrated into their current practices.

Tips: Networking at events provides an invaluable opportunity to learn about the latest industry trends. Don’t hesitate to ask questions and seek demonstrations; hands-on experiences can lead to a deeper understanding of innovative solutions.

The 138th China Import and Export Fair in 2025 showcased a wide array of innovations in cable assembly solutions, reflecting the rapid advancements and emerging trends that cater to diverse industries. As sectors such as telecommunications, automotive, and renewable energy expand, the demand for more efficient, reliable, and adaptable cable assemblies has surged. Exhibitors presented cutting-edge technologies, including modular designs, eco-friendly materials, and smart connectivity features, aligning with the industry's shift toward sustainability and efficiency.

Significantly, the fair highlighted the increasing importance of customization in cable assembly solutions. Manufacturers are responding to the unique requirements of various applications by offering tailored solutions that enhance performance and reduce installation time. The integration of automation and artificial intelligence in the production process also emerged as a notable trend, streamlining operations and improving quality control. As industries evolve, the innovations presented at the fair underscore a commitment to meeting the dynamic needs of the market while fostering collaboration among manufacturers, suppliers, and end-users.

At the recent 138th China Import and Export Fair 2025, sustainability took center stage in the cable assembly sector. The industry is witnessing a significant shift towards eco-friendly practices, driven by increasing regulatory pressures and consumer demand for sustainable products. According to a report by MarketsandMarkets, the global market for eco-friendly cable assembly is projected to reach $10 billion by 2027, growing at a CAGR of 8.4% from 2022. This growth is propelled by innovations in materials, such as the use of bioplastics and recycled metals, which not only reduce environmental impact but also improve the overall efficiency of cable assemblies.

Furthermore, major companies are adopting circular economy principles within their operations. Companies like Nexans and Southwire are leading the charge by implementing waste reduction strategies and investing in renewable energy for manufacturing processes. A study by the International Cable & Connectivity Industry revealed that adopting sustainable practices can reduce costs by up to 30% while enhancing brand reputation among eco-conscious consumers. As cable assembly innovations continue to evolve, the focus on sustainability will undoubtedly shape the future landscape, ensuring that the industry not only meets current demands but also contributes positively to environmental conservation.

The 138th China Import and Export Fair 2025 presents an unparalleled opportunity for cable assembly professionals to network and forge valuable connections within the industry. As one of the largest trade fairs in the world, this event gathers a diverse array of exhibitors and visitors, creating a vibrant ecosystem for sharing innovative ideas and practices. The fair features dedicated showcases for the latest advancements in cable assembly technologies, where professionals can engage in discussions with leading manufacturers, suppliers, and industry experts.

Attendees will benefit from numerous networking sessions designed to facilitate collaboration and partnership among key stakeholders. These opportunities allow professionals to exchange insights, explore potential business ventures, and gain exposure to emerging trends shaping the cable assembly landscape. Whether through formal meetings, workshops, or informal gatherings, the fair fosters an environment where relationships are cultivated, ultimately driving growth and innovation in the cable assembly sector. As the industry evolves, participating in such networking opportunities will be essential for professionals looking to stay ahead of the curve.

| Event Date | Location | Expected Attendees | Key Topics | Networking Sessions |

|---|---|---|---|---|

| April 15 - 19, 2025 | Guangzhou, China | 20,000+ | Cable Assembly Technologies, Industry Standards, Future Trends | Panel Discussions, One-on-One Meetings |

| April 15, 2025 | Guangzhou International Convention Center | 5,000+ | Best Practices in Assembly, Automation in Cabling | Roundtable Sessions, Networking Lunches |

| April 16 - 17, 2025 | Guangzhou Import and Export Fair Complex | 10,000+ | Advanced Materials for Cable Assembly | Speed Networking, Expert Panels |

At the 138th China Import and Export Fair 2025, the spotlight is on how digital transformation is revolutionizing cable assembly manufacturing techniques. As industry reports indicate, the global market for cable assembly is projected to reach USD 111.48 billion by 2028, growing at a CAGR of 6.2% from 2021. This growth is largely driven by advancements in automation and data analytics, which are streamlining production processes and enhancing efficiency.

The implementation of digital technologies, such as IoT and AI, in cable assembly production allows manufacturers to monitor and analyze operational performance in real-time. According to a McKinsey report, manufacturers that adopt digital solutions can reduce production costs by up to 30% while improving product quality and delivery times. This shift not only elevates the competitive edge of manufacturers but also enables them to meet the rising demand for customized and complex cable assemblies in various sectors, including automotive and aerospace.

Tips: For manufacturers looking to thrive in this digital era, investing in employee training on new technologies is essential. Additionally, collaborating with tech partners to integrate smart solutions into existing systems can facilitate smoother transitions and foster innovation. Embracing these changes can pave the way for a more efficient and responsive manufacturing environment.