In the realm of audio engineering, understanding Vacuum Tube Parts is crucial for achieving that rich, warm sound many enthusiasts crave. Renowned expert Dr. Mike Smith, a veteran in the field, remarks, “Knowing your vacuum tube parts can transform your sound experience.” This underscores an essential truth: familiarity with these components can lead to greater satisfaction in audio quality.

Vacuum tubes have unique characteristics, often requiring specific parts for optimal performance. Key components include the filament, cathode, and anode, each playing a vital role in the tube’s functionality. However, many overlook the importance of selecting the right parts. Quality can vary greatly across brands, leading to confusion and dissatisfaction.

It's common for newcomers to feel overwhelmed by the variety of vacuum tube parts available. Yet, this knowledge is essential. It can be frustrating to find the right match for your equipment. Taking time to explore and understand these parts is a worthy investment. It leads to improved sound clarity and enhances the overall listening experience.

Vacuum tube technology has made a significant comeback. This resurgence is due to its warm sound and unique characteristics. Many audiophiles and musicians appreciate vacuum tubes for their tonal qualities. According to a recent industry report, about 43% of audio enthusiasts prefer tube amplification over solid-state alternatives.

The parts of vacuum tubes are intricate yet crucial. These components, such as cathodes and anodes, play a vital role in the tubes' operation. The cathode emits electrons when heated, creating the flow necessary for amplification. However, every part needs careful selection. A poorly chosen component can lead to suboptimal performance. This reality reflects a challenge facing enthusiasts. Balancing quality and availability is an ongoing struggle.

Another aspect to consider is the maintenance of these parts. Regular checks ensure longevity and reliability. Over time, vacuum tubes can wear out, impacting sound quality. Data suggests that about 25% of users report issues related to aging tubes. Knowing when to replace them can transform the listening experience. Navigating the world of vacuum tubes requires dedication, focus, and a bit of trial and error.

Understanding vacuum tubes requires knowledge of their key components. Each part has a specific function that contributes to the tube's overall performance. The cathode emits electrons when heated, forming a vital gas flow. The anode collects these electrons, enabling current flow. The control grid modulates this flow, determining amplification levels.

A power supply is essential. It provides the necessary voltage for proper operation. Filaments within the vacuum tube heat the cathode. They play a critical role in initializing the electron emission process. Don’t overlook the envelope; it protects the inner components from air contamination.

Tips: Ensure your tubes are well-maintained. Regular checks on connections help avoid unexpected failures. Be cautious with voltage levels; too high may damage components. Every part matters, so keep an eye on wear and tear. Recognizing these details can lead to better sound quality in audio applications.

In vacuum tubes, cathodes and anodes play crucial roles. The cathode emits electrons when heated. This process is essential for the tube's operation. The anode, positioned opposite the cathode, collects these electrons. The movement of electrons between these two components creates the electrical current that the vacuum tube controls.

Tips: Always check the cathode material. Some materials last longer than others. A good cathode can make a difference in performance.

Understanding these parts is key to grasping how vacuum tubes function. If the cathode is weak, the entire tube's performance suffers. It may lead to distortion in sound or signal. Observing the tube's response can highlight potential issues. Frequent testing is beneficial.

Tips: Anodes can overheat if the tube is misused. Monitor the tube's temperature regularly. Heat management is vital for longevity. A simple thermoelectric sensor can assist with this.

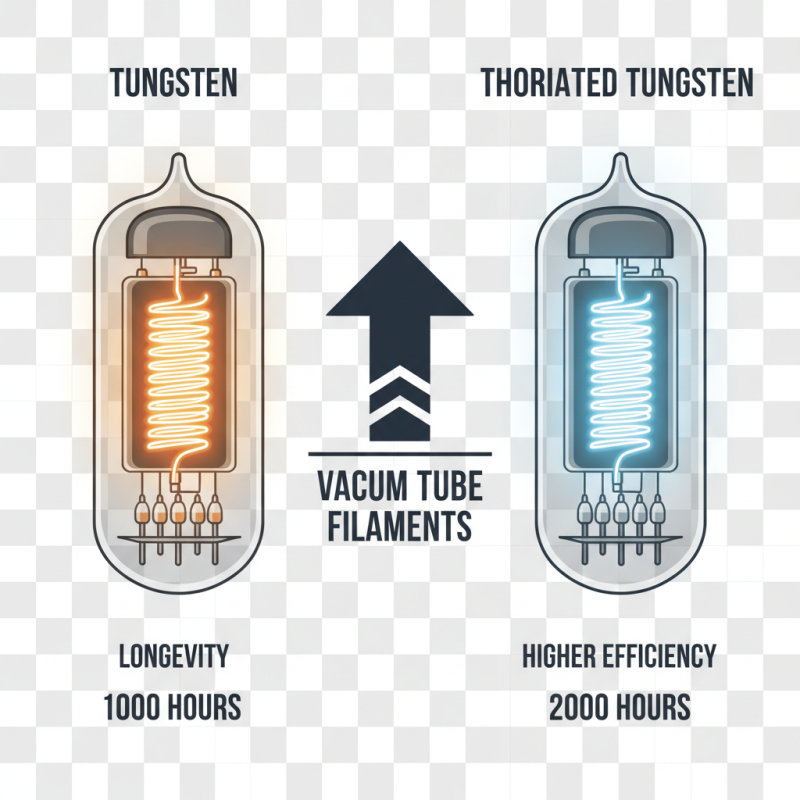

In the world of vacuum tubes, filaments are crucial components. They provide the necessary heat to create electrons needed for amplification. The material of the filament can significantly affect performance. Common materials include tungsten and thoriated tungsten. Tungsten filaments offer great longevity, with lifespans reaching up to 1,000 hours. In contrast, thoriated tungsten can deliver higher efficiency, boasting up to 2,000 hours in some applications.

However, not all filaments perform equally. Variability in manufacturing processes can lead to inconsistencies. Factors such as impurities or uneven wire thickness impact performance. The choice of filament affects sound quality and device reliability. An informed decision on filament material can make a difference in audio fidelity.

**Tip:** When selecting vacuum tube parts, consider the specific application requirements.

Furthermore, filament construction shapes behavior under load. Thin filaments heat up quickly but may burn out faster. Thick filaments are more robust but can take longer to warm up. The balance between heat and durability is essential, especially in high-stress environments.

**Tip:** Always aim for the right balance in filament choice for optimal performance.

In the end, understanding filament materials leads to better choices. This knowledge is critical for both hobbyists and professionals in the audio world. Making a choice based solely on brand reputation can lead to disappointments.

Vacuum tube bases are essential components in the world of audio electronics. They provide the connection between the tube and the circuit board. Without a proper base, a vacuum tube cannot function effectively. Different types of bases exist, each with specific applications. Some bases are designed for high-power tubes, while others serve smaller, low-power applications.

The most common bases include the octal, noval, and miniature types. Octal bases feature eight pins and are often used in larger tubes. Noval bases are smaller, with nine pins, ideal for compact space applications. Miniature bases have even fewer pins, but they are versatile and useful in many devices. Understanding these variations is crucial for anyone working with vacuum tubes.

Unfortunately, selecting the wrong base can lead to performance issues. It’s essential to consider compatibility and application requirements. Many enthusiasts may overlook these details, leading to frustration. A microscopic oversight can have significant consequences. Therefore, mindful selection is key in maximizing the benefits of vacuum tube technology.