When it comes to selecting the ideal glass tube for your specific needs, understanding the various types available is crucial. Glass tubes come in a multitude of shapes, sizes, and materials, each tailored for different applications ranging from scientific experiments to industrial processes. The right choice can significantly impact both the functionality and efficiency of your project. In this blog, we will delve into the different types of glass tubes, their unique characteristics, and the factors you should consider when making your selection.

Whether you are a seasoned professional or new to working with glass tubes, our comprehensive guide will help you navigate the options and make an informed decision that aligns with your objectives. Discover how to choose the right glass tube that not only meets your requirements but also enhances your overall results.

When selecting glass tubes for laboratory use, there are several critical factors that should guide your decision.

First, consider the type of material. Borosilicate glass is renowned for its thermal resistance and chemical durability, making it ideal for high-temperature applications, while soda-lime glass is suitable for general-purpose use. According to a recent industry report by Smithers Pira, the global demand for borosilicate glass in laboratories is expected to grow by 4.5% annually over the next five years due to its superior properties.

Another pivotal factor is the size and dimensions of the glass tube. Selecting the appropriate diameter and length is essential for ensuring compatibility with laboratory equipment and achieving accurate results. For instance, smaller diameter tubes are predominantly used for chromatography applications, where precision is critical. Additionally, standardized tubing sizes ensure easier sample handling and maintain uniformity in experimental conditions.

Tips: Always verify the compatibility of the glass tube with the chemicals you plan to use. For highly reactive substances, opt for tubes with higher resistance ratings. Also, consider the sealing options; some experiments may require glass tubes with special end treatments to prevent contamination. Lastly, ensure that the glass tubes meet industry-specific regulations to avoid compliance issues.

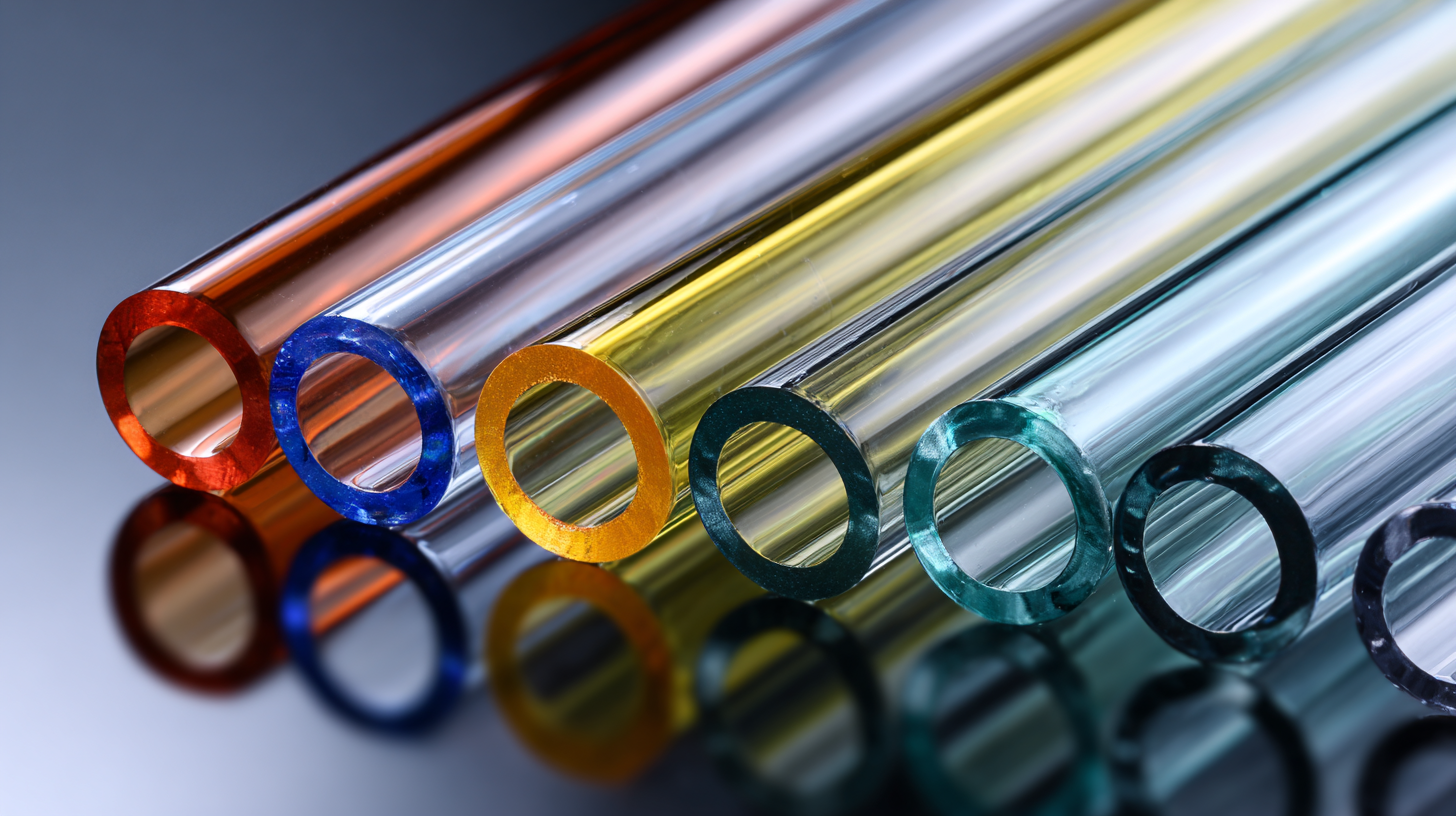

When it comes to selecting the right glass tube for your specific applications, understanding the various types of glass tubes available is crucial. Glass tubes come in different sizes, shapes, and compositions, each suited for unique tasks. For instance, borosilicate glass tubes are known for their excellent thermal resistance and are commonly used in laboratory settings for chemical experiments. Their ability to withstand temperature fluctuations makes them ideal for applications that involve heating or cooling.

On the other hand, soda-lime glass tubes are more cost-effective and are widely used in everyday products and packaging. These tubes are suitable for non-critical applications where high precision is not a necessity. Furthermore, there are specialized glass tubes, such as quartz tubes, which offer high transparency and superior UV resistance. They are often employed in fiber optic applications and in high-temperature environments. By understanding these distinctions, you can make informed decisions that align with your needs, ensuring efficiency and safety in your operations.

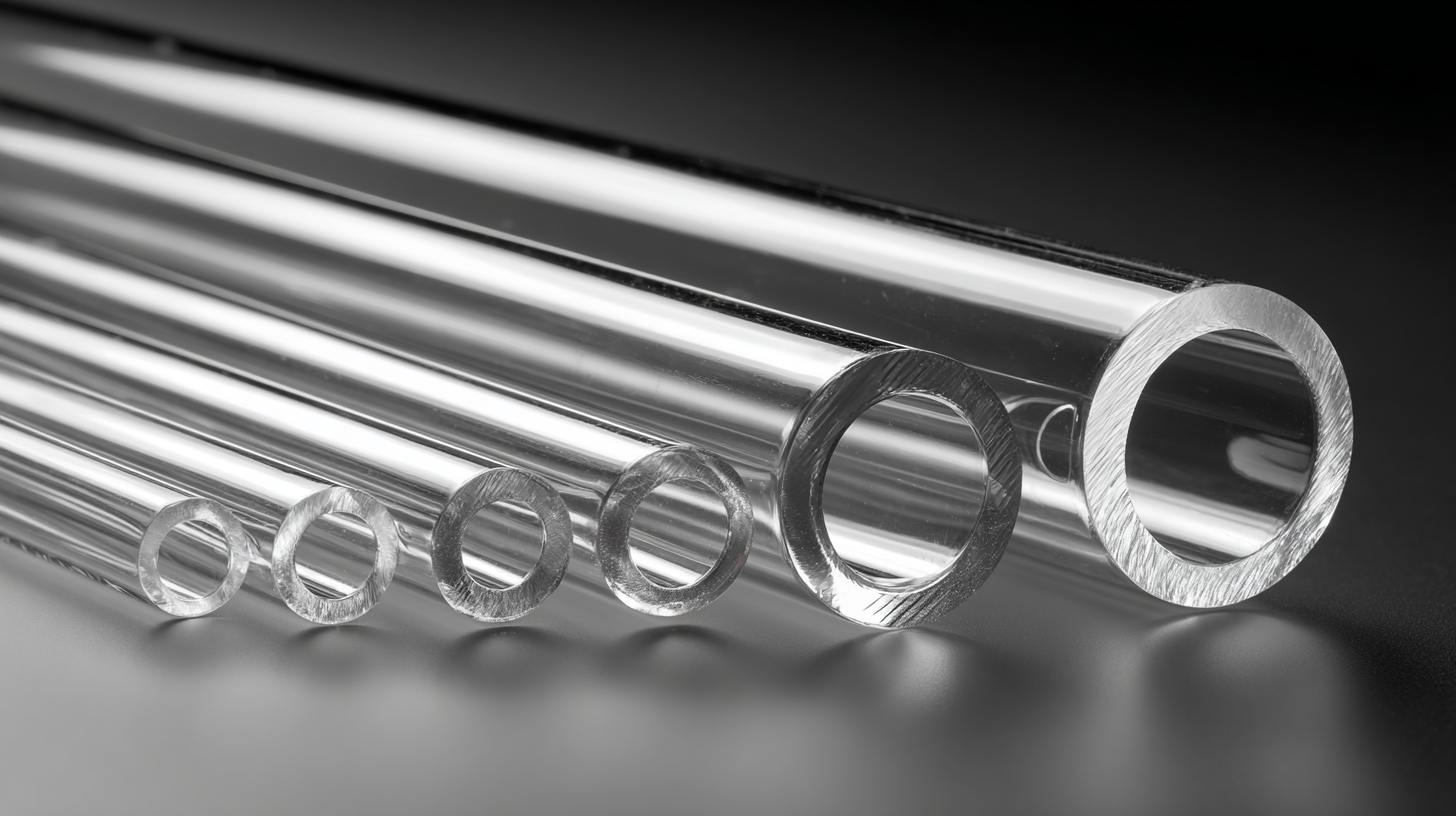

When selecting the right glass tube, determining the appropriate size and thickness is crucial for fulfilling your specific needs. The diameter and length of the tube should align with your application requirements—whether you’re using it for laboratory experiments, decorative purposes, or industrial applications. Consider the volume of substances you need to contain or transport; larger diameters allow for increased flow rates, while longer tubes may be necessary for specific setups. Carefully assessing these dimensions can prevent potential issues related to functionality and efficiency.

In addition to size, the wall thickness of the glass tube plays a vital role in its performance. Thicker glass provides greater strength and resilience, making it suitable for high-pressure applications or environments with risk of impact and breakage. Conversely, thinner glass is generally lighter and more cost-effective for projects where high durability is not a primary concern. It’s essential to balance your needs with the characteristics of the glass to ensure optimal performance, longevity, and safety in your chosen application.

When selecting glass tubes for your projects, it's crucial to avoid common pitfalls that can lead to inefficiencies and increased costs. One of the most prevalent mistakes is failing to consider the specific application of the tube. Different projects require different types of glass, such as borosilicate for high-temperature applications or soda-lime glass for general use. Understanding the specific conditions under which the tube will be used—such as temperature fluctuations, chemical exposure, and mechanical stress—is essential for making the right choice.

Another common error is not measuring accurately. Miscalculating dimensions can lead to significant problems during installation or when using the tubes in fittings. Always double-check your measurements and consider the thickness of the glass, as it can vastly impact performance and durability.

Tip: When in doubt, consult with suppliers or experts in the field who can provide insights based on your specific requirements. This can save time and prevent costly mistakes down the line. Additionally, consider purchasing samples before making a bulk order. Testing with actual materials can help ensure they meet your project's needs effectively.

When it comes to maintaining and storing glass tubes, proper care is essential to ensure their longevity and functionality. One of the best practices is to store glass tubes in a clean, dry environment. Avoid areas where they might be exposed to extreme temperatures or humidity, as these factors can weaken the glass over time. Using dedicated storage containers with padding can prevent accidental breakage and protect the tubes from dust and contaminants.

Regular inspection of glass tubes is also crucial. Before and after use, check for any signs of chipping or cracks, which can compromise their integrity. Additionally, consider labeling the tubes based on their intended use to minimize cross-contamination. When cleaning, opt for gentle methods; avoid abrasive materials that could scratch the surface. By following these best practices, you can extend the life of your glass tubes and maintain their clarity and quality, ensuring they remain reliable for your specific needs.