When embarking on DIY projects or crafting, choosing the right metal wire is essential. Metal wire comes in various types, each suited for specific applications. The selection can be overwhelming. Different projects demand different qualities, such as flexibility, strength, or conductivity.

Consider the various types of metal wire. For instance, aluminum wire is lightweight and easy to work with. Copper wire, on the other hand, offers excellent conductivity. This makes it ideal for electrical projects. Steel wire is known for its strength, making it perfect for structural components.

Navigating these options can lead to confusion. What works for one project may not work for another. It’s crucial to understand the specific needs of your project. Investing time in research can lead to better results. After all, the right metal wire can make a significant difference in the success of your project.

When choosing metal wire for projects, understanding the types is vital. Common materials include steel, aluminum, copper, and brass. Each offers unique properties suited for specific applications. For instance, steel wire is known for its strength. It boasts tensile strength ranging from 350 to 2000 MPa, making it ideal for construction and heavy-duty tasks.

Aluminum wire, on the other hand, is lightweight and resistant to corrosion. This makes it popular in electrical applications where weight is a concern. A report by the Aluminum Association highlights that aluminum wire conducts electricity well, having about 61% the conductivity of copper for less weight.

Copper wire remains a strong contender, especially in electronics. Its excellent conductivity and flexibility are advantageous for wiring. However, it is more expensive than aluminum and steel. Brass combines the benefits of copper and zinc, creating a wire that is both malleable and strong. These diverse materials demand careful consideration during selection. Selecting the wrong type may lead to performance issues, such as poor conductivity or structural failure.

Aluminum wire is known for its lightweight nature and versatility. It’s ideal for various projects, from crafting to electrical applications. Working with aluminum wire can be rewarding, but it does require some care. It’s softer than steel, making it easier to shape but also more prone to bending or breaking under stress.

When using aluminum wire, pay attention to its gauge. A thinner wire might work for light projects, but thicker gauges offer more strength. If your project requires durability, opt for a thicker aluminum wire. Remember, testing the wire before full use can save time and frustration.

Tip: Always wear protective gloves while working with wire. Sharp edges can cause cuts. Another tip is to store aluminum wire in a cool, dry place. This prevents oxidation that can weaken the wire over time. Working with aluminum can be a fun experience, but be mindful of its properties.

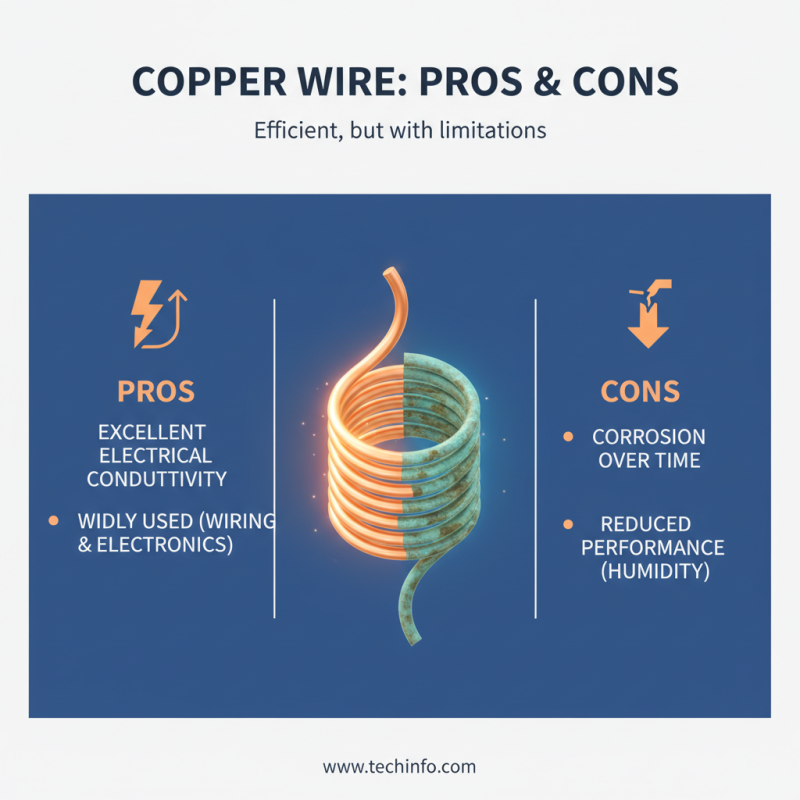

Copper wire stands out due to its remarkable electrical conductivity. It is widely used in various projects, particularly in wiring and electronics. Its ability to transmit electricity efficiently makes it a popular choice. However, copper does have its downsides. Over time, it can corrode, especially in humid environments. This can lead to reduced performance.

Durability is another major factor for copper wire. When properly insulated, it can last a long time. Some projects may expose the wire to harsh conditions. In these situations, it’s worth considering the environment. A little forethought can prevent issues down the line.

On the other hand, copper wire is often heavier than other metals. This may complicate some designs. Its weight can be a challenge when flexibility is needed. Adjusting to these factors is essential. Finding the right balance between conductivity and practicality is key. While copper wire is a solid choice, being mindful of its limitations helps in creating better outcomes.

Steel wire is a popular choice for various projects due to its remarkable strength. It can withstand significant tension and pressures without breaking. This makes it ideal for construction and heavy-duty applications. Many builders rely on steel wire to ensure the stability of structures. It serves as an anchor in many scenarios where support is crucial.

Another important aspect of steel wire is its resistance to corrosion. This feature allows it to endure exposure to moisture and harsh conditions without deteriorating quickly. For instance, outdoor installations often utilize galvanized steel wire to enhance longevity. However, even galvanized steel can eventually show signs of wear. Regular inspections are necessary to identify potential weaknesses over time.

While steel offers impressive benefits, it is not impervious to all challenges. Users must consider the specific requirements of their projects. For some situations, the stiffness of steel might be a limitation. Flexibility is important in certain applications, and alternatives may need to be explored. Understanding the unique demands of each project is essential for success.

Specialty wires can greatly enhance your projects. They offer unique properties tailored for specific applications. For example, nichrome wire is often used in heating elements. This wire is known for its high resistance to heat and oxidation. It can withstand temperatures exceeding 1,000 degrees Fahrenheit. Such capabilities make it ideal for equipment that requires efficient heating.

Another interesting option is stainless steel wire. It is famed for its strength and corruption resistance. In fact, reports indicate that stainless steel wire can last significantly longer than regular steel in harsh environments. This advantage makes it a top choice for marine applications. However, working with stainless steel requires proper tools and techniques. Beginners might struggle, leading to potential mistakes.

Lastly, consider copper wire. Its excellent conductivity makes it valuable for electric projects. Yet, copper wire is prone to oxidation over time. This can affect performance and reliability. Users should be cautious about the environment in which they use it. Additionally, specialty wires often come at a premium cost. Evaluating whether the benefits outweigh the price is essential for any project.