Alloy Wire is a crucial material in various industries, playing a vital role in manufacturing and construction. According to Dr. Emily Carter, an expert in metallurgical engineering, “Alloy Wire is often the unsung hero in engineering applications.” This statement emphasizes the significance of this versatile wire.

In aerospace and automotive sectors, Alloy Wire offers strength and resistance to extreme temperatures. It is invaluable for components like turbine engines and exhaust systems. In the medical field, Alloy Wire is used in surgical instruments and implants, where precision and reliability matter deeply. The diversity in its applications often leads to overlooked opportunities for innovation.

However, the industry faces challenges. Not all manufacturers understand the importance of material selection, which can affect performance. Misapplication of Alloy Wire can lead to failures, prompting a need for continuous education. The journey toward mastering Alloy Wire’s capabilities requires reflection on past mistakes and a commitment to quality.

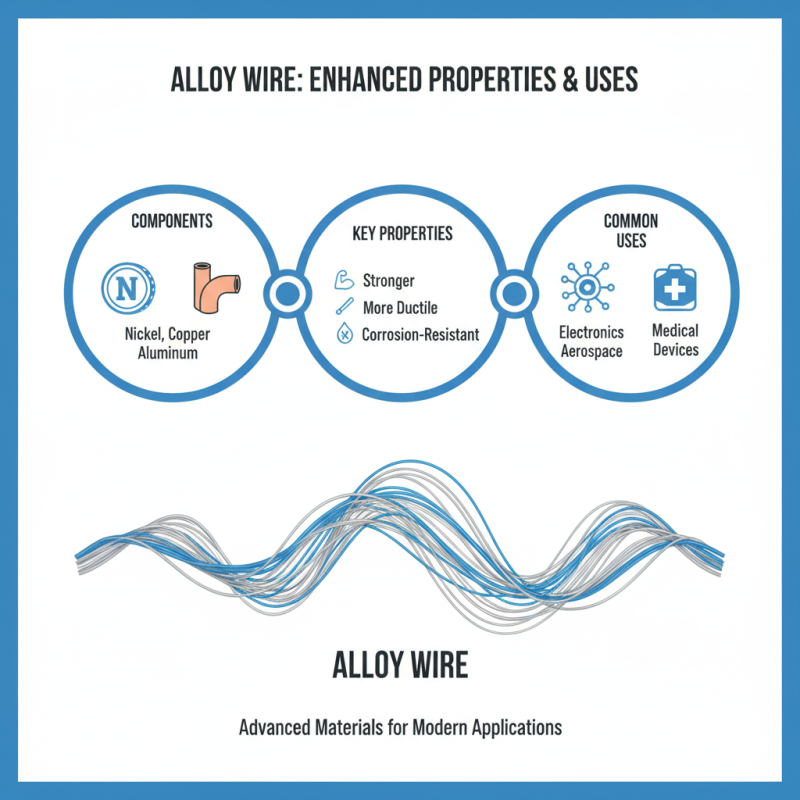

Alloy wire is a specific type of wire made from a mixture of metals. This combination enhances its properties for various uses. The most common materials in alloy wire include nickel, copper, and aluminum. These elements create a wire that is stronger, more ductile, and resistant to corrosion. Such properties make alloy wires popular in various applications.

In construction, alloy wires are ideal for reinforcing concrete. They provide strength, enabling structures to withstand heavy loads. In the automotive industry, these wires are crucial for electrical components. They ensure efficient conductivity while minimizing weight. However, some manufacturers struggle to maintain consistent quality in alloy wire production. This inconsistency can lead to unexpected failures.

In electronics, alloy wires play a vital role in circuits. They offer reliability and precision. Having the right composition is essential to prevent downtime. Miscalculations in alloying can result in significant disruptions. As industries continue to evolve, so does the need for smarter, more resilient alloy wire solutions. Investing in research and development will be important for future applications.

Alloy wires are essential in many industries due to their unique properties. They are made from a mix of different metals, enhancing strength, corrosion resistance, and conductivity. One notable type is stainless steel alloy wire. It combines iron with chromium and nickel, offering amazing rust resistance. This wire type finds uses in construction and medical instruments.

Another common type is nickel alloy wire. This wire is typically used in high-temperature applications. It can withstand harsh environments without losing its integrity. Additionally, copper alloy wire is widely used in electronics. It provides excellent electrical conductivity and flexibility, perfect for intricate wiring.

Different alloy wires have unique characteristics. Some might be too brittle for certain applications. It’s important to choose the right type for the job. In some cases, alloy wires may not perform as expected. Evaluating performance under specific conditions is critical. Making mistakes is part of the process, leading to better choices in the future.

| Type of Alloy Wire | Composition | Properties | Applications |

|---|---|---|---|

| Stainless Steel Wire | Iron, Chromium, Nickel | Corrosion-resistant, high tensile strength | Medical devices, kitchenware, construction |

| Nickel Alloy Wire | Nickel, Copper, Manganese | High temperature stability, excellent corrosion resistance | Aerospace, chemical processing, electronics |

| Copper Alloy Wire | Copper, Zinc, Tin | Good electrical conductivity, malleability | Electrical wiring, automotive connectors, plumbing |

| Titanium Alloy Wire | Titanium, Aluminum, Vanadium | Lightweight, high strength-to-weight ratio | Medical implants, aerospace components, marine applications |

Alloy wire is a versatile material used extensively in manufacturing. Its unique properties make it suitable for various industrial applications. For instance, in automotive and aerospace industries, alloy wire is utilized for making strong yet lightweight components. These components often undergo rigorous testing, which sometimes reveals unexpected weaknesses.

In the electronics sector, alloy wire serves a vital role in connecting circuit boards. The precision of these connections can affect overall device functionality. While engineers strive for perfection, small errors in wire thickness or placement can lead to significant issues. Regular inspections are essential to identify any potential flaws in the production process.

Medical devices also benefit from alloy wire. Surgical instruments and implants require high strength and biocompatibility. Manufacturers often face challenges in meeting exact specifications. Each device must be carefully tested. Any oversight could result in serious consequences. This constant pressure to excel can sometimes lead to hurried work, reminding us that quality control should never be compromised.

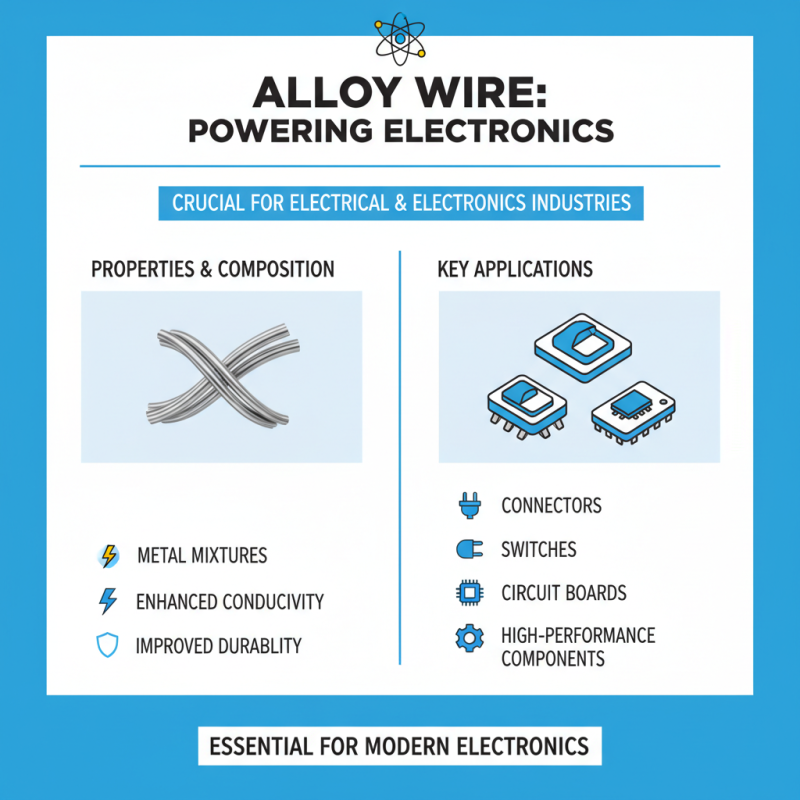

Alloy wire plays a crucial role in the electrical and electronics industries. These wires are made from various metal mixtures, enhancing their conductivity and durability. They are often used in the manufacturing of electrical components, such as connectors, switches, and circuit boards. This wire type has unique properties that make it ideal for high-performance applications.

In electronics, alloy wire can improve efficiency and longevity. The wire’s resistance to corrosion is essential in harsh environments. High-temperature applications benefit from its ability to maintain strength without compromising performance. Despite these advantages, not all alloy wires are suitable for every application. Sometimes, the choice of alloy may lead to unexpected failures, prompting careful consideration during the design process.

The growing demand for miniaturization in devices also affects alloy wire choices. Designers now focus on wires that are thinner yet strong. The balance between size and performance can be challenging. When using alloy wires in precise applications, one must remain mindful of trade-offs. This complexity underscores the importance of ongoing research and development in the field.

The future of alloy wire technology is exciting and full of possibilities. Recent industry reports indicate that the global alloy wire market is expected to reach $XX billion by 2025, growing at a CAGR of YY%. This growth is primarily driven by advancements in manufacturing techniques and the increasing demand for specialized wire types in aerospace and medical sectors.

One notable trend is the development of lightweight and high-strength alloy wires. These materials are essential in aerospace applications, where weight reduction can lead to significant fuel savings. In addition, there is a shift towards eco-friendly production processes. Manufacturers are exploring sustainable raw materials and recycling options. A report by industry experts states that companies adopting green practices see a 20% increase in consumer trust.

However, challenges remain. The fluctuating prices of raw materials can impact production costs. Moreover, not all manufacturers can keep up with the pace of innovation. The gap in technological capabilities may hinder smaller companies from competing effectively. As the industry evolves, there’s a need for better collaboration across sectors, fostering innovation while addressing these hurdles.